The chemical industry is one of the world’s most important economic sectors and its products have directly or indirectly found their way into all areas of daily life. In the chemical industry, our products, especially chain conveyors are used to transport fertilizer, detergent powders, and plastic pellets or powders. These industries demand making of conveyor technologies keeping in mind some factors like corrosion, wear & tear, thermal stress, explosion protection and most importantly bulk material transport method. Their special requirements are our challenge – no matter whether chains, sprockets and/or conveyor components are involved, and we are keen to deliver them.

Modern agriculture is no longer imaginable without fertilizers. The fertilizer industry is made up of companies who represent the entire supply chain from production to distribution to retail, all working together to deliver fertilizer to farmers in a safe, timely, and sustainable manner. Belt Conveyor System is an indispensable part in the whole fertilizer production line. We provide customers with inclined belt conveyor and high inclination-angle belt conveyor. The inclined conveyor connects main fertilizer equipment together, making an easier raw materials & finished products transportation. The material handling conveyors are used in incline and decline applications to glow fertilizers to be accumulated while moving between floors or stacked conveyor. It saves labor, time and energy, with characters of high efficiency & easy operation. When worn out, these plates can easily be removed.

Dairy farming has been an important part of the agricultural scenario for thousands of years. India being a predominantly agrarian economy has about 70 percent of its population living in villages. India is not only one of the top producers of milk in the world, but also the largest consumer of milk and milk products in the world. Conveyors move raw materials and finished products through a dairy plant. After filling, packages might travel to secondary packaging stations, to freezers, to warehouses and to pallets. Conveyors may specify clean out ports, spray nozzles, belts lifts, easily removable carry and return way components. Sanitary features should include standoffs for frame mounted elements, sanitary supports and washdown rated power transmission components.

Pharmaceuticals have been used to treat illnesses for thousands of years. The early days of medication included plants and herbal remedies to treat a variety of diseases and traumas. Today, the long and complex journey to demonstrate the safety and efficacy of a compound and bring it from the laboratory into the hands of patients in need, is a multi-billion-dollar global industry. During pharmaceutical production, conveyors are integral in safely transporting pharmaceuticals for manufacturing, packaging, and distribution. A pharma conveyor belt must meet stringent sanitary requirements, typically set by governing bodies like the FDA, to ensure the safety of products within the facility. An ideal pharmaceutical belt conveyor will be easy to clean and help minimize cross-contamination of materials during transit from one area to another.

Sugar industry is an important agro-based industry that impacts rural livelihood of about 50 million sugarcane farmers and around 5 lakh workers directly employed in sugar mills. Employment is also generated in various ancillary activities relating to transport, trade servicing of machinery and supply of agriculture inputs. India is the second largest producer of sugar in the world after Brazil and is also the largest consumer. Today Indian sugar industry’s annual output is worth approximately Rs.80,000 crores. Moving sugar cane from harvest through pocessing requires top-quality chains that can stand up to abrasion, corrosion and high shock loads at ever increasing production rates. Time matters during harvest. Count on Renold Jeffrey to move product from field to market, fast. Our chains are manufactured to the highest standards to deliver value in the most demanding applications.

Rolling is a continuous process, during which the input material is deformed between the rotating work rolls. Rolling mill is the place where rolling takes place. The roll gap (a gap between the work rolls) is smaller than the material entry height. As per the direction of passing the rolling stock between the work rolls, the position of rolls axes in relation to the rolling stock, and the course of rolling, a rolling mill can be categorized into longitudinal rolling mill, cross- rolling mill, and diagonal rolling mill. Roller conveyors or roller tables are essential to rolling mill plants and their regular operation. Rolling mills use roller conveyors to carefully move material from point A to point B without human intervention. The entire function of roller tables is to ensure efficient and speedy movements of various materials, which is why they are commonly used in rolling mills. For a roller conveyor to operate smoothly, there needs to be at least one rigid or almost flat object to touch the rollers and retain steady equilibrium. Some of the most primary materials that roller tables carry are steel billets, slabs, bars, ingots, plates and more.

Asphalt drum mix commonly known as the hot mix plant is the greatest mixer of concrete, asphalt, coarse and fine aggregate and filler material to create a homogeneous mix at the necessary temperature. Hot mix plants are used mostly for road construction. The cold aggregate mixer is used to spread and create the base and minimum level of a road; meanwhile, the hot aggregate is used to create the final layer of the road. Our commitment to quality and excellence has put us firmly on the Industrial Map of India. Our Road Construction Machinery like, Asphalt Drum Mix Plants, Asphalt Batch Mix Plants, Concrete Batching Plant, Self Loading Mixers, Bitumen Sprayers, Road Sweepers, etc. have been used and tested in the extremes of conditions and have passed each assignment with flying colors.

Industrial dryers are used to efficiently process large quantities of bulk materials that need reduced moisture levels. Depending on the amount and the makeup of material needing to be dried, industrial dryers come in many different models constructed specifically for the type and quantity of material to be processed. Industrial Multi-layer Conveyor Belt Dryer is a drying device that uses a steel mesh as a conveyor belt to carry out continuous drying. Since the conveyor belt is in the form of a mesh, it is suitable for drying rules or irregularities of various masses (for example, coal mass, various mineral powder molding, food, vegetables, etc.). The equipment can be widely used in building materials, ceramics, fertilizer, chemical and other industries.

The conveyor system in the painting factory is an automatic transportation system that is involved in the entire process from receiving the car body from the welding factory, passing through the painting process, and handing over the car body to the assembly factory. This conveyor is a skid-type overhead conveyor applied to pretreatment and electrodeposition processes. The treatment process is chain transportation. It is transported by the roller bed method. The work (automobile body) is mounted on the skid. The skid is automatically mounted by two U-shaped arms attached to the chain. The empty hanger to be returned is returned with the U-shaped arm folded at the bottom of the device.

The cement industry has important economic significance due to its long and diversified supply chain contributing 5.4 per cent of global GDP and 7.7 per cent of global employment. The Indian cement industry is majorly dominated by regional players, since cement being a bulk commodity, transporting it over long distances is not economical and non-viable. In cement plants, multiple kinds of conveying equipment are needed from the feeding, material transmission to the discharging and warehousing. It is conveying equipment that connects other equipment in the cement production line as a whole. As a professional cement plant manufacturer, AGICO offers three types of conveying equipment for cement plant projects: cement feeder, cement conveyor, and bucket elevator. AGICO also offers overland conveyors for the long-distance transportation of bulk materials, and heavy duty conveyor belts.

The food industry is a complex, global network of diverse businesses that supplies most of the food consumed by the world's population. The food industry today has become highly diversified, with manufacturing ranging from small, traditional, family-run activities that are highly labour-intensive, to large, capital-intensive and highly mechanized industrial processes. Conveyor systems have revolutionized the food industry by speeding up the transportation of materials between long distances, cutting down on human labor, and minimizing manual handling. This technology allows for a more sanitary environment with less dirt getting into production areas that can lead to illness or contamination, which has also helped increase product safety. To fully appreciate the benefit of food processing conveyor systems, we need to understand why they were invented and their role in food production.

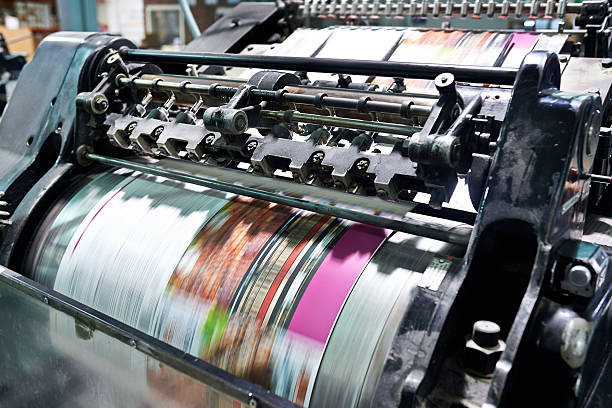

The printing press allows us to share large amounts of information quickly and in huge numbers. In fact, the printing press is so significant that it has come to be known as one of the most important inventions of our time. It drastically changed the way society evolved. Driving chain as an important part is widely used in large-scale printing machinery. It ensures that the tooth row can collect paper from the impression cylinder accurately. From the perspective of the printing process, chain can reduce the transmission power required for the sheets separation to improve work efficiency and save labor costs.